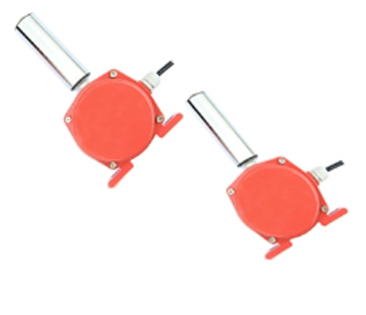

Product Overview:PB10-45 belt correction switch is a safety device used to monitor and adjust the deviation of belt conveyors. When the belt deviates during operation, PB10-45 can detect the deviation and issue an alarm, or automatically correct it to protect the equipment and reduce the risk of accidents. This device is widely used in industrial fields, especially in mining, power, metallurgy, chemical and other industries.

Main features:

High precision detectionAdopting advanced sensor technology, it can monitor the running status of the belt in real time, quickly detect and respond to deviation situations.

Automatic correction functionIn addition to issuing an alarm, the device also has an automatic correction function, which can automatically adjust the position of the belt and restore its normal trajectory.

durableThe equipment casing is made of high-strength materials, which have excellent impact resistance and corrosion resistance, and are suitable for various harsh industrial environments.

High protection levelThe protection level reaches IP65, waterproof and dustproof, ensuring that the equipment can still operate stably in harsh environments.

Multiple signal outputsSupport normally open and normally closed contact signal output, able to adapt to different control system requirements.

Technical parameters:

working principle:The PB10-45 belt correction switch monitors the operating status of the belt through a built-in high-precision sensor. Once the belt deviates from the normal track and reaches the set detection angle, the equipment will trigger an internal switch, issue an alarm signal or activate the automatic correction function. This correction function adjusts the running direction of the belt to restore it to its normal trajectory.

Application scenarios:

Installation and maintenance:

Installation locationThe PB10-45 belt correction switch should be installed at key locations of the belt conveyor, such as on both sides of the belt, to ensure timely detection of belt deviation.

Wiring debuggingFollow the product manual for wiring and preliminary debugging to ensure correct connection of equipment power and signal lines. After installation, debug and check whether the alarm and correction functions of the equipment are normal.

Regular maintenanceRegularly inspect the appearance and internal wiring of the equipment to ensure that there is no damage or looseness. It is recommended to clean regularly to prevent dust accumulation from affecting the detection sensitivity of the equipment.

functional testingIt is recommended to conduct functional testing on the equipment every quarter to ensure that it can promptly issue an alarm and perform corrective actions when detecting belt deviation.

Safety precautions:

Summary:The PB10-45 belt correction switch is an important device to ensure the safe operation of the belt conveyor system. It can accurately monitor the running status of the belt, issue timely alarms or automatically correct deviations, prevent production accidents and equipment damage caused by deviation, and is suitable for belt protection applications in various industrial conveyor systems.

1. What is the detection accuracy of PB10-45 belt correction switch?

The PB10-45 belt correction switch has high-precision detection capability and can accurately detect the deviation of the belt. Its sensor design is advanced, capable of quickly responding to slight deviations in the belt and triggering alarms or automatic correction functions to ensure the safe operation of the equipment.

2. Is the PB10-45 belt correction switch suitable for high temperature environments?

The PB10-45 belt correction switch is suitable for a working temperature range of -25 ° C to+70 ° C. For applications in high-temperature environments, it is recommended that users take appropriate cooling measures during installation or choose additional protective devices to extend the service life of the equipment.

3. How to perform daily maintenance on PB10-45 belt correction switch?

Daily maintenance includes regular inspections of the appearance and internal wiring of the equipment to ensure that there is no damage or looseness. Users also need to regularly clean the surface of the equipment to prevent dust accumulation from affecting detection sensitivity. In addition, functional testing should be conducted quarterly to ensure that the equipment can accurately respond when detecting belt deviation.

4. Does the PB10-45 belt correction switch support automatic reset function?

The PB10-45 belt correction switch has an automatic reset function. When the device detects that the belt has returned to its normal position, it will automatically reset and resume normal operation without manual intervention. This helps to improve the operational efficiency of the conveying system and reduce the frequency of manual operations.