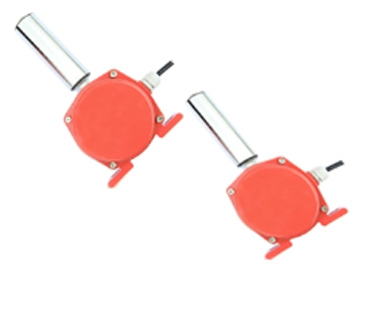

The deviation switch FSPK-20-35 is a safety protection device designed specifically for belt conveyors, mainly used to detect whether the conveyor belt deviates during operation. When the conveyor belt deviates from the normal track, the deviation switch FSPK-20-35 will issue an alarm or stop signal to avoid equipment damage or safety accidents. This product has the characteristics of high sensitivity, sturdy and durable structure, and easy installation, and is widely used in various industrial conveying systems.

The working principle of the deviation switch FSPK-20-35 is based on the cooperation between the roller and the internal micro switch. When the conveyor belt deviates from the normal running track, it drives the roller of the deviation switch to deflect, and the roller triggers the micro switch through the lever arm, thereby issuing a stop or alarm signal. This signal can be transmitted to relevant equipment through the control system to ensure that the conveyor belt stops running and prevent further damage.

The deviation switch FSPK-20-35 is suitable for various belt conveyor systems, especially in heavy industries such as coal mines, ports, metallurgy, chemical engineering, and power plants. This device can maintain stable operation in extreme working environments, providing efficient and reliable safety guarantees for the conveyor system, and preventing equipment failures or personnel injuries caused by conveyor belt deviation.

The deviation switch FSPK-20-35, with its high sensitivity, sturdy and durable design, and easy installation and maintenance, has become an indispensable safety protection device in belt conveyor systems. It can effectively prevent equipment damage and production accidents caused by conveyor belt deviation, and is an important means to ensure production safety in modern industrial fields.

1. How does the deviation switch FSPK-20-35 work?

FSPK-20-35 detects the offset of the conveyor belt through rollers. When the conveyor belt deviates from the normal track by more than 20 degrees, the roller triggers the internal micro switch, issuing an alarm or shutdown signal to prevent equipment damage or accidents. After the conveyor belt returns to its normal position, the switch will automatically reset.

2. What are the applicable scenarios for FSPK-20-35 deviation switch?

FSPK-20-35 is suitable for belt conveyor systems in industries such as coal mining, metallurgy, chemical engineering, and power plants, especially when working in harsh environments. It can prevent the conveyor belt from deviating, avoid production line failures and safety hazards.

3. What are the maintenance points for the deviation switch FSPK-20-35?

Regularly clean the rollers and lever arms to prevent dust accumulation from affecting sensitivity. Regularly test its sensitivity to ensure that the switch can respond normally when the conveyor belt deviates. At the same time, check whether the electrical wiring is secure to prevent poor contact from causing misoperation or failure.