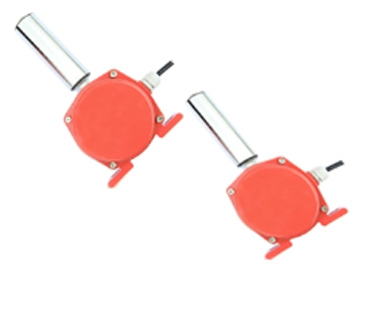

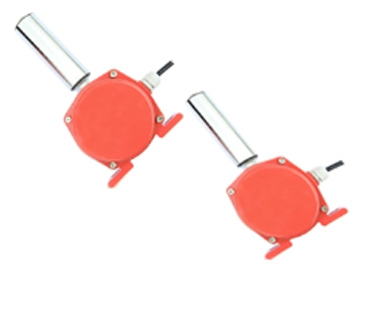

Product Overview:

ELAM-10 deviation switch is a safety device used in conveyor belt systems, specifically designed to monitor the deviation status of the conveyor belt. When the conveyor belt deviates, ELAM-10 can quickly detect and issue an alarm signal, and if necessary, it can automatically stop to avoid equipment damage or accidents. This device is widely used in transportation systems in industries such as coal mines, steel, chemicals, and power plants to ensure the safety and stability of the production process.

Main functions:

- Real time monitoring of conveyor belt deviation:It can quickly and accurately detect the deviation of the conveyor belt, preventing damage to the equipment caused by deviation.

- Automatic alarm and shutdown:When the conveyor belt deviates from the set angle, the device will automatically issue an alarm signal or stop to ensure safety.

- High protection level:Suitable for harsh working environments, it has good impact resistance, dust resistance, and waterproof performance.

Technical parameters:

- model:ELAM-10

- Detection angle: 10°

- Working voltage:AC 220V / 380V

- Contact capacity:AC 380V / 5A

- Output method:Normally open and normally closed contact outputs

- Protection level:IP65

- Working temperature:-25 ℃ to+70 ℃

- texture of material:Cast aluminum casing

- Weight:2.8kg

Product features:

- High precision detection:ELAM-10 adopts high-sensitivity sensors to ensure timely alarm or shutdown when the conveyor belt deviates.

- Durable and reliable:The shell is made of cast aluminum material, which has good corrosion resistance and is suitable for long-term continuous operation.

- Widely applicable:It can be used in various industrial environments and is suitable for harsh working conditions, such as high temperature and dusty environments.

Application scenarios:

ELAM-10 deviation switch is suitable for conveyor belt systems, especially in industries with high safety requirements such as coal mines, power plants, ports, and chemicals. It can effectively prevent production stoppages, material leaks, or equipment damage caused by conveyor belt deviation.

Installation and maintenance:

- Installation method:The deviation switch should be installed on both sides of the conveyor belt and adjusted appropriately according to the specific width and angle of the conveyor belt.

- Regular inspection:To ensure long-term stable operation of the device, sensor sensitivity and external wiring should be regularly checked.

- Easy maintenance:Keep the switch surface clean to avoid foreign objects blocking and affecting equipment performance.

Precautions for use:

- Detection angle setting:During installation, it is necessary to adjust the detection angle according to the characteristics of the conveyor belt to ensure the normal operation of the equipment.

- Wiring inspection:Ensure correct wiring during installation to avoid misoperation or invalid alarms.

- Environmental conditions:When using, extreme temperatures and humidity should be avoided from exceeding the working range of the equipment to prevent affecting its performance.

Related Q&A FAQs:

1. What is the detection angle of ELAM-10?

The detection angle of ELAM-10 deviation switch is 10 °, which can quickly respond to the deviation of the conveyor belt.

2. What industrial environments is ELAM-10 suitable for?

ELAM-10 is suitable for industries such as coal mines, power plants, ports, steel, and chemicals. It can work in harsh environments such as dust and humidity, with a protection level of IP65.

3. Does ELAM-10 support automatic shutdown function?

Yes, ELAM-10 can automatically trigger the shutdown function when detecting the deviation of the conveyor belt from the set angle, avoiding further damage to the conveyor belt system.