Product Overview

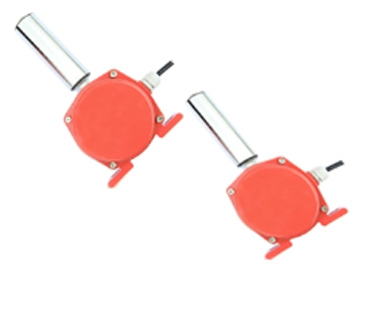

The deviation switch HFKPT1-10-45 is a high-performance deviation detection device designed specifically for conveyor belt systems. It can monitor the running status of the conveyor belt in real time, detect deviation phenomena in a timely manner, and issue alarms to prevent equipment damage and production interruption. HFKPT1-10-45 adopts advanced sensor technology and reliable design, aiming to enhance the safety and stability of the production line.

Product Features

High sensitivity detectionHFKPT1-10-45 is equipped with a high-sensitivity sensor that can accurately detect the offset of the conveyor belt. Whether it is a slight deviation or a large offset, the equipment can respond quickly to ensure timely alarm and guarantee the normal operation of the conveyor belt.

durableThe equipment is made of industrial grade materials and has excellent wear resistance and corrosion resistance. Its shell design complies with industrial standards and can work stably for a long time in harsh environments such as mines, power plants, and chemical plants.

Flexible adjustmentHFKPT1-10-45 supports adjustment of sensitivity and detection angle. Users can make adjustments according to their actual needs to ensure that the equipment can adapt to different conveyor belt operating states and working environments, thereby providing the best detection results.

Easy installationThe device design takes into account the convenience of installation, providing clear installation instructions and simple installation methods. Users can quickly complete the installation and debugging of equipment, reducing the time it takes to put the equipment into use.

Reliable output modeSupports normally open (NO) and normally closed (NC) contact outputs, compatible with various alarm systems and control devices, meeting the needs of different systems and ensuring the reliability of the alarm system.

technical parameter

application area

The deviation switch HFKPT1-10-45 is widely used in industries such as coal mining, power, metallurgy, building materials, and chemical engineering. Specially suitable for deviation monitoring of belt conveyors, it can effectively prevent equipment failures and production interruptions caused by belt deviation, ensuring the safe and stable operation of the production line.

Installation and use

Installation locationInstall HFKPT1-10-45 onto the brackets on both sides of the conveyor belt, ensuring coverage of all possible offset areas of the conveyor belt. During installation, it is necessary to ensure that the equipment is stable and avoid affecting its working effect due to vibration or impact.

wiring methodFollow the electrical wiring diagram in the product manual to ensure that the power and signal lines are connected correctly, in order to avoid wiring errors that may cause equipment malfunction.

debuggingAfter installation, the equipment needs to be debugged. Adjust the detection angle and sensitivity to ensure that the equipment can accurately respond to the deviation of the conveyor belt. After debugging, it is recommended to conduct actual operational testing to confirm whether the device settings meet the actual requirements.

maintainRegularly check the working status and appearance of the equipment, keep the sensor part clean, and prevent dust and foreign objects from affecting the detection effect. Regularly conduct functional testing to ensure the normal operation of the equipment.

matters needing attention

after-sale service

We provide comprehensive after-sales service for the HFKPT1-10-45 deviation switch, including technical support, troubleshooting, and parts supply. If you encounter any problems during use, please contact the technical support team in a timely manner, and we will provide you with timely assistance and solutions.

summary

The deviation switch HFKPT1-10-45 provides reliable assurance for the safe operation of the conveying system with its high-precision detection capability, durable design, and flexible adjustment function. Whether in the coal mining, power, or chemical industries, HFKPT1-10-45 is an ideal choice to ensure stable and safe operation of production lines. By choosing HFKPT1-10-45, you will receive an efficient and reliable solution for deviation detection.

1. What industries is HFKPT1-10-45 suitable for?

HFKPT1-10-45 is widely used in industries such as coal mining, power, metallurgy, building materials, and chemical engineering. It is particularly suitable for monitoring the deviation of belt conveyors, which can effectively prevent equipment failures and production interruptions caused by belt deviation, ensuring the safe and stable operation of the production line.

2. How to install and maintain HFKPT1-10-45?

When installing HFKPT1-10-45, fix the equipment on the brackets on both sides of the conveyor belt to ensure that the equipment is stable and can cover the possible offset area of the conveyor belt. Please follow the electrical wiring diagram in the instruction manual when wiring to ensure correct connection. Regularly check the equipment status, keep the sensor part clean, avoid dust affecting the detection effect, and ensure the normal operation of the equipment.

3. What is the protection level of HFKPT1-10-45?

The protection level of HFKPT1-10-45 is IP65. This means that the equipment has excellent dust and water resistance, suitable for industrial environments with high dust and humidity, such as mines and chemical plants, and can effectively protect internal components from external environmental influences.