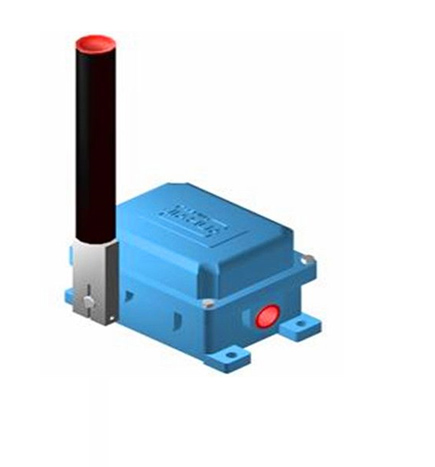

Product Overview:The XLPP-II belt conveyor universal deviation switch is an anti deviation monitoring device designed specifically for belt conveyor systems. This product can monitor the deviation of the belt in real-time during operation and issue an alarm signal when the deviation exceeds the set limit. By timely detection and alarm, the XLPP-II deviation switch can effectively prevent equipment damage and production stoppage caused by belt deviation, and is widely used in belt conveyor systems in industries such as mining, coal, ports, and chemical.

Main features:

High sensitivity monitoringEquipped with precision sensors, it can quickly and accurately detect the deviation of the belt, ensuring timely alarm signals.

Durable designMade of high-strength and durable materials, it has good dustproof, waterproof, and anti-corrosion properties, suitable for use in various harsh industrial environments.

Wide applicabilityThis switch has strong universality and is suitable for various types of belt conveyors, providing reliable anti deviation protection.

Easy installation and maintenanceCompact design, easy to install, and equipped with detailed installation and debugging guidelines for easy maintenance.

Technical parameters:

working principle:The XLPP-II deviation switch monitors the real-time running status of the belt through a built-in high-precision sensor. When the belt deviates and exceeds the preset angle or distance, the sensor will immediately trigger the switch and issue an alarm signal. According to the degree of belt deviation, the switch can be set to trigger different levels of alarms to remind operators to perform corrective operations in a timely manner, thereby avoiding belt damage or production accidents.

Application scenarios:

Installation and maintenance:

Installation location selectionInstall the XLPP-II deviation switch in a position where the belt is prone to deviation, ensuring that the sensor of the switch is parallel to the belt to achieve the best detection effect.

Wiring and DebuggingConnect the power cord according to the wiring diagram in the product manual, and after installation, perform system debugging. Simulate the deviation of the belt, check if the alarm function of the switch is normal, and adjust the detection angle and alarm threshold as needed.

Regular maintenanceRegularly inspect the casing and sensors of the switch to ensure that the equipment is not damaged or loose. Clean the surface of the sensor to avoid dust and foreign objects affecting the detection effect. Especially in high dust or high humidity environments, maintenance frequency should be increased.

Safety precautions:

Summary:The universal deviation switch of XLPP-II belt conveyor provides a reliable anti deviation solution for various industrial belt conveyor systems due to its high sensitivity, high durability, and wide applicability. It can effectively monitor and prevent belt deviation, ensuring the normal operation and production safety of equipment, and is suitable for use in various complex industrial environments.

1. How reliable is the XLPP-II deviation switch in extreme environments?

The XLPP-II deviation switch is designed to be dustproof, waterproof, and corrosion-resistant, meeting the IP67 protection level, and can operate stably in harsh industrial environments. Its shell is made of corrosion-resistant alloy material, which can resist extreme temperature, humidity, and chemical erosion, ensuring long-term use in high-risk environments such as mines and chemical plants.

2. How to install and debug XLPP-II deviation switch?

When installing the XLPP-II deviation switch, choose a position where the belt is prone to deviation and install the sensor parallel to the belt. After wiring, debug by simulating the belt offset situation to ensure that the switch works normally within the set detection angle. During debugging, the alarm threshold can be adjusted according to actual needs to achieve the best detection effect.

3. How can XLPP-II deviation switch improve the safety of belt conveyor system?

The XLPP-II deviation switch monitors the running status of the belt in real time and can immediately issue an alarm signal when the belt deviates, reminding the operator to take corrective measures. This can effectively prevent equipment damage and production accidents caused by belt deviation, thereby greatly improving the safety and reliability of the belt conveyor system.

4. What is the maintenance frequency of XLPP-II deviation switch?

Under normal working conditions, it is recommended to perform maintenance once every quarter, checking the casing, sensors, and electrical connections of the switch. In high dust or high humidity environments, it is recommended to increase maintenance frequency, such as once a month, to ensure that the equipment is always in good operating condition. Regular cleaning and inspection of equipment can extend its lifespan and maintain its optimal performance.