Product Overview:

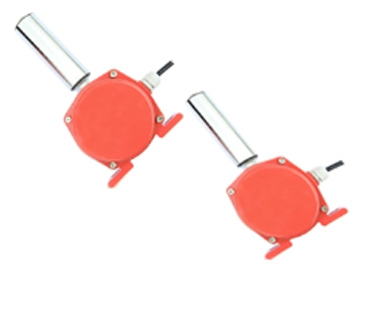

The KGE20 deviation switch is a protective device designed specifically for belt conveyor systems, aimed at detecting and preventing deviation of the conveyor belt during operation. This switch is suitable for multiple industrial fields such as coal mining, metallurgy, chemical engineering, and power. By monitoring the deviation of the belt in real time, it can promptly issue alarm signals or automatically shut down, effectively protecting equipment and ensuring production safety.

working principle:

The KGE20 deviation switch uses swing arms installed on both sides of the conveyor belt to detect belt deviation. When the belt deviates, the swing arm will be moved, triggering the micro switch inside the switch. According to the set angle, the switch will output an alarm signal or a shutdown signal. This device usually provides dual level protection function, which can issue an alarm in case of slight deviation and trigger a shutdown in case of severe deviation to prevent further equipment damage.

Product features:

Technical parameters:

Application scenarios:

Installation and maintenance:

matters needing attention:

Summary:

KGE20 deviation switch is an efficient and reliable belt conveyor protection device that can accurately detect the deviation status of the belt, promptly issue alarm or shutdown signals, and ensure the safe operation of the conveyor system. Its dual level protection mechanism and sturdy and durable design make it perform well in various industrial environments, making it an ideal choice for protecting conveying equipment.

1. What are the alarm and shutdown angles of KGE20 deviation switch?

The KGE20 deviation switch is equipped with a dual level protection mechanism. The alarm angle is 12 °, and an alarm signal will be issued when the belt deviates slightly; The shutdown angle is 30 °. When the belt deviates severely, a shutdown signal will be triggered to protect the equipment from further damage.

2. What industrial environments is the KGE20 deviation switch suitable for?

The KGE20 deviation switch has an IP65 protection level and is suitable for harsh environments with high levels of dust and moisture. It is widely used in fields such as coal mining, metallurgy, chemical engineering, and electricity, and can work stably in these industrial environments to ensure the safe operation of belt conveyor systems.

3. How to install and maintain KGE20 deviation switch?

When installing, the switch should be fixed on both sides of the conveyor belt, and the swing arm should be kept at a distance of 30-50 millimeters from the edge of the belt. Regularly check the flexibility of the swing arm and the triggering status of the switch, and clean the dust and debris around the switch to ensure that the equipment is working properly. In addition, regularly check whether the wire connectors are secure to avoid affecting equipment functionality due to looseness.