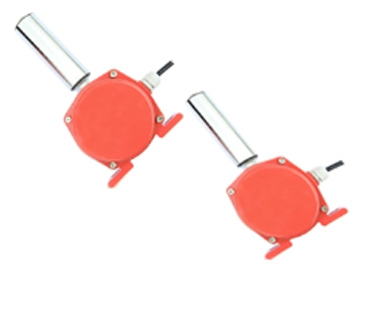

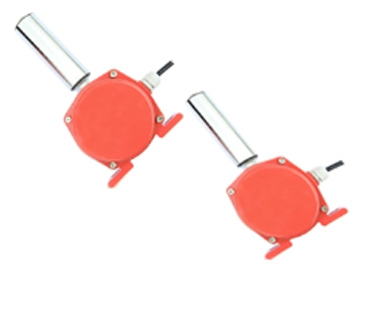

Product Overview

The ST28-BKPT1-10-45 deviation switch is a safety protection device used in conveyor belt systems. Its main function is to monitor the deviation of the conveyor belt. When the conveyor belt deviates, the deviation switch can promptly issue an alarm signal or trigger a shutdown, avoiding equipment damage and safety accidents. This device is widely used in industries such as coal mining, steel, ports, electricity, and chemical engineering, and is one of the indispensable safety devices in transportation systems.

Product Features

- high sensitivityThe ST28-BKPT1-10-45 deviation switch can quickly sense the deviation of the conveyor belt, ensuring timely response.

- durableMade of high-strength alloy materials, corrosion-resistant and impact resistant, suitable for long-term use in harsh working environments.

- Easy to installSmall size, compact structure, easy to install on both sides of the conveyor belt, and convenient for installation and debugging.

- High protection levelThe product has an IP65 protection level, dustproof and waterproof, suitable for various industrial environments, especially outdoor places.

- Adjustable detection angleThe detection angle can be adjusted according to the needs to adapt to different conveyor belt systems and improve monitoring accuracy.

technical parameter

- modelST28-BKPT1-10-45

- working voltage: AC 220V / DC 24V

- Detection angle: 10 ° -45 ° (adjustable)

- contact rating: 5A/250V AC

- Protection level: IP65

- working temperature-30 ℃ to+70 ℃

- Shell material: Cast aluminum

- weight: 3.2kg

working principle

The ST28-BKPT1-10-45 deviation switch is installed on both sides of the conveyor belt to monitor the real-time running trajectory of the conveyor belt. When the conveyor belt deviates from the normal operating path and reaches the set detection angle, the switch will act and send a signal, and the control system will alarm or stop the machine through this signal, thereby avoiding equipment damage or safety accidents caused by deviation.

application area

- Mining industryDetect whether the belt transporting coal or ore is offset to prevent production interruption or equipment damage caused by deviation.

- Power industryEnsure stable operation of the conveyor belt in the fuel delivery system of the power plant to prevent unexpected shutdowns.

- Metallurgical industryMonitor the belt system that transports materials during the steel production process to avoid production line failures caused by material deviation.

- Chemical industryUsed for conveying chemical materials to ensure the safety and continuity of the production process.

- Port terminalMonitor the transportation process of bulk materials such as coal, ore, and grains to avoid system failures.

Installation and Debugging

- Installation locationThe deviation switch should be installed on both sides of the conveyor belt, near the critical position where deviation may occur.

- Adjust the angleAdjust the detection angle according to the operating status of the conveyor belt, usually within the range of 10 ° -45 °, to ensure monitoring sensitivity and accuracy.

- Wiring and DebuggingConnect the switch to the control system according to the electrical wiring diagram and perform functional testing after ensuring proper connection.

- functional testingSimulate deviation situations and check if the equipment can respond promptly and issue alarm signals or shut down.

Maintenance and upkeep

- Regular inspectionRegularly inspect the mechanical components of the equipment for wear or looseness, ensuring that the switch action is sensitive and reliable.

- Cleaning and maintenanceKeep the surface of the switch clean to avoid dust and material accumulation affecting its detection effect.

- Lubrication and maintenanceRegularly lubricate the mechanical components of the switch to ensure smooth operation.

matters needing attention

- Installation stabilityEnsure a secure installation and avoid the switch becoming loose due to conveyor belt vibration or external forces.

- Adjust the angle appropriatelyAdjust the detection angle of the deviation switch to make it neither too sensitive nor too slow, avoiding false alarms or delayed responses.

- Environmental adaptabilityAvoid using the equipment beyond its specified temperature range or under extreme humidity conditions to ensure its long-term reliability.

conclusion

The ST28-BKPT1-10-45 deviation switch is widely used in conveyor belt systems due to its high sensitivity, durability, and ease of installation, ensuring the safe operation of production lines. It not only improves the operational stability of the conveyor equipment, but also greatly reduces the production safety hazards and equipment damage risks caused by conveyor belt deviation.

Related Q&A FAQs:

1. What industries is the ST28-BKPT1-10-45 deviation switch suitable for?

This deviation switch is widely used in various industries such as coal mining, power, metallurgy, chemical engineering, and ports. It is mainly used to monitor the deviation status of conveyor belts and ensure the safe operation of the system.

2. How to adjust the detection angle of this device?

The detection angle of the ST28-BKPT1-10-45 deviation switch can be adjusted between 10 ° and 45 °, and users can set it according to the actual operation of the conveyor belt.

3. How to ensure the long-term stable operation of the deviation switch?

Regularly inspect and maintain the equipment, keep the switch surface clean, lubricate the moving parts regularly, and ensure that the installation is firm and the detection angle is appropriate to ensure its long-term stable operation.