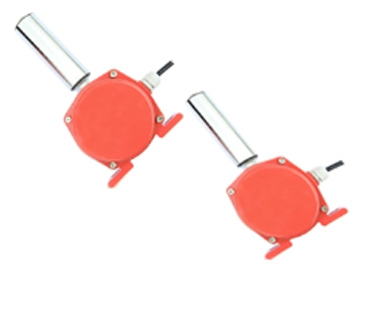

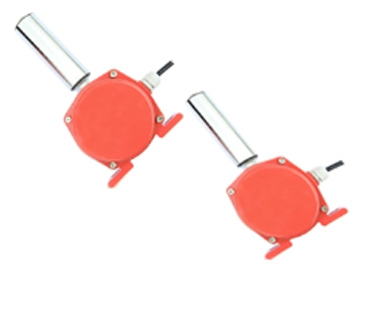

Product Overview

FPPKG-22-30 deviation switch is a safety protection device for belt conveyors, specifically designed to detect and prevent belt deviation. Its main function is to issue an alarm signal or control the conveyor to stop running when the conveyor deviates from the normal trajectory, preventing equipment damage and production accidents. This switch is widely used in industries such as mining, metallurgy, ports, and chemical engineering due to its high sensitivity and strong environmental adaptability.

Product Features

- High sensitivity detectionWhen the conveyor belt deviates beyond the predetermined angle, FPPKG-22-30 can respond quickly to ensure safe operation.

- Durable and sturdy designAdopting high-strength cast aluminum shell, it has excellent impact resistance and corrosion resistance, suitable for various complex environments.

- Action and reset angleThe default action angle is 22 °, and the reset angle is 30 °, ensuring timely detection even when the conveyor belt is slightly offset.

- Automatic reset functionAfter the conveyor belt returns to normal, the switch will automatically reset without manual intervention, reducing downtime.

- IP65 protection levelEffectively dustproof and waterproof, ensuring that the equipment can maintain stable performance even in harsh environments.

technical parameter

- model: FPPKG-22-30

- Action angle:22°

- Reset angle:30°

- contact rating:AC 220V 5A

- Protection level:IP65

- texture of materialCast aluminum casing

- supply voltage:AC/DC 24V、110V、220V(可选)

- working temperature-25 ℃ to+70 ℃

- Installation methodBolt fixed on both sides of the conveyor belt

- weightApproximately 3kg

working principle

The working principle of FPPKG-22-30 deviation switch is to detect the deviation angle of the conveyor belt. When the deviation of the conveyor belt from the normal trajectory reaches 22 °, the micro switch inside the switch is triggered, issuing an alarm or shutdown signal to prevent the conveyor belt from being damaged due to severe deviation. When the conveyor belt returns to its normal track and the offset angle is less than 30 °, the switch will automatically reset to ensure the continuous operation of the conveyor system.

Application scenarios

FPPKG-22-30 deviation switch can be applied in various industrial fields, especially in dusty, humid or corrosive environments. Typical application scenarios include:

- Coal mine: used to prevent the risk of fire and mechanical damage caused by conveyor belt deviation.

- Metallurgical industry: Protect production equipment to avoid downtime or damage caused by conveyor belt deviation.

- Ports and terminals: Ensure the safe operation of conveyor belts during the transportation of bulk cargo.

Installation and Debugging

- Installation locationFix the deviation switch on both sides of the conveyor belt and adjust the roller to maintain slight contact with the conveyor belt to ensure accurate detection angle.

- Electrical connectionConnect the wiring according to the required voltage to ensure proper connection with the shutdown control system or alarm system.

- Angle adjustmentBy adjusting the device to set appropriate actions and reset angles, ensure that the equipment can respond promptly when the conveyor belt deviates slightly.

- Run testAfter installation, conduct a test by manually offsetting the conveyor belt to check if the switch can accurately detect and issue an alarm signal.

Maintenance and upkeep

- Regular inspectionCheck the flexibility of the rollers and the connection of the electrical components once a month to ensure that the equipment maintains good performance during long-term use.

- Cleaning and lubricationTimely clean the dust and dirt on the surface of the equipment, and regularly lubricate the rollers and mechanical parts to ensure their sensitivity and service life.

- Replace componentsIf damaged or worn switch components are found, they should be replaced in a timely manner to avoid equipment failure affecting production.

epilogue

FPPKG-22-30 deviation switch is an important safety device for conveyor belt systems, which can provide quick response when the conveyor belt deviates, prevent equipment damage and safety accidents. Its sturdy design and high performance make it an indispensable protective device in industrial production.

Related Q&A FAQs:

1. Can the action angle of FPPKG-22-30 deviation switch be adjusted?

The default action angle of FPPKG-22-30 is 22 °, and the reset angle is 30 °. These two perspectives can be adjusted according to specific needs to adapt to different operating environments. Users can set appropriate detection angles based on the operation of the conveyor belt.

2. What industrial environments is FPPKG-22-30 suitable for?

The FPPKG-22-30 deviation switch adopts a cast aluminum shell with a protection level of IP65, which has good dustproof, waterproof and corrosion-resistant performance. It is suitable for industrial environments with high dust, humidity or corrosive gases, such as coal mines, metallurgy, ports, chemical industries, etc.

3. How to maintain the deviation switch FPPKG-22-30?

Maintaining FPPKG-22-30 requires regular checks on the flexibility of the rollers, ensuring stable electrical connections, regularly cleaning dust, and providing lubrication for mechanical components. If any parts are found to be worn or damaged, they should be replaced in a timely manner to ensure the long-term stable operation of the equipment.